Deep-Diving into the Art and Science Behind Crafting the Perfect Pickleball

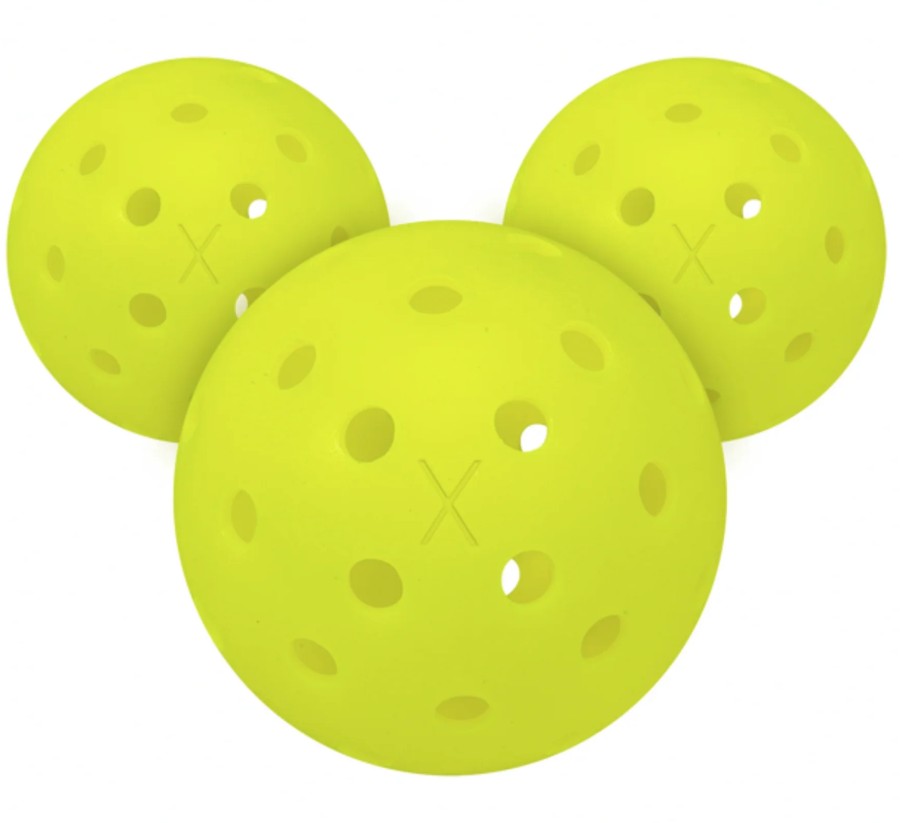

Pickleball—once a backyard novelty—is now the world’s fastest-rising sport, captivating millions across continents and gaining unprecedented momentum in Asia’s burgeoning courts. And right in the sweet spot of this pickleball revolution are those plastic balls whose distinctive “thwack” is one of the sport’s defining features.

But how exactly are these balls made?

The secrets are plastic engineering and precision manufacturing

Polymers to Performance: The Core of Pickleball Production

Behind that hollow, perforated ball soaring across the net lies a marvel of material science. The humble pickleball is typically crafted from polyethylene (PE) or polypropylene (PP)—lightweight yet resilient polymers chosen for durability and playability. But that’s not even the good stuff. The real magic lies in how these polymers are shaped and turned into pickleballs.

Two dominant manufacturing methods are used in this case: rotational moulding (a.k.a. rotomoulding) and injection moulding. Rotational moulding involves moulding the polymer with precision, delivering dynamic flight characteristics that produce a faster ball, which is the preferred choice for advanced players. Injection moulding, on the other hand, involves injecting molten resin into moulds, yielding more durable but slightly slower balls that are perfect for beginners and casual gameplay.

“Generally speaking, the rotational moulded ball produces a faster ball, which is preferred by more advanced players,” noted Riley Burgess, Vice President of Equipment Compliance at USA Pickleball (USAP). “Injection moulded balls usually are more durable and slightly slower, which is better for beginner players.”

That distinction somehow favours injection moulding, which is the undisputed choice when it comes to manufacturing plastic balls for pickleball en masse, as the technique can produce a huge number of balls in less time, with less complexity, and with fewer issues. It is also more economical compared to rotomoulding.

“Injection moulding is a better option as you can control a lot of potential issues from arising. You can produce a considerably larger number of balls in the same amount of time it takes to make roto,” said Angel Morales, Chief Development Officer of Professional Pickleball Partners, a.k.a. Pro-Pickle. “Rotomoulding is a lot more complex as you have a lot of things that will cause unwanted variance in hardness, wall thickness, bounce, durability, and other factors. Cost is usually higher as well, but, up until more recently, this was the only way to make a truly high-performance pickleball.”

Even the number of holes in every ball, regardless of resin, must be precise—right around 26 larger-sized holes for indoor balls and approximately 40 smaller sized holes for outdoor balls. These holes must be strategically placed to reduce air drag, minimise wind interference, and maintain flight stability. They should also be drilled using precision drilling for consistency across large numbers of balls.

According to Morales, Pro-Pickle is striving to supercharge the manufacturing of high-performance balls using state-of-the-art moulding. The ultimate goal is to be able to mass-produce fast, dynamic balls so that they can be used not just in pro-level tournaments but also in casual games between regular, everyday picklers.

Material Choice Matters and the Drive Towards Sustainability

Moreover, resin formulation—whether PP or PE is used and in what amounts—also matters a lot. It matters mostly because the kind of resin dictates how a ball will perform given court conditions.

For instance, indoor pickleballs are primarily made of PE resins, which are known for their flexibility and controlled rebound characteristics. According to Morales, PE resins are softer and provide predictable bounce on smooth indoor surfaces while also maintaining structural integrity.

Outdoor variants, on the other hand, are mostly composed of the more rigid PP compounds and engineered to withstand UV exposure, temperature fluctuations, and abrasion from rough playing surfaces. But because PP resins are more rigid and hard, outdoor balls typically exhibit faster speeds even when used in more challenging playing conditions.

Aside from the manufacturing technique used and the resin makeup of the balls, manufacturers like Pro-Pickle are now grappling with another important consideration: sustainability. With the meteoric rise of pickleball, millions upon millions of plastic balls are being sold globally—and it might not necessarily be what’s best for the environment, especially when you consider plastic’s not-so-good reputation as an environmental hazard.

Burgess and the USAP are aware of the possible environmental impact of pickleball’s growing footprint, and so are Morales and Pro-Pickle. In fact, according to Burgess, sustainability has “become more top of mind recently,” prompting USAP to take a closer look at the balls being released in the market.

Pro-Pickle’s Compost-a-Ball, made of a patented blend of wheat straw and rice husk, might be worth an even closer look. These balls, according to Morales, are compostable and break down in about 100 days only, which means they leave less waste and can improve soil health. These balls will get their turn in the spotlight in the World Pickleball Cup in October, and their superb performance could go a long way in the drive towards sustainability.

Pickleball’s Understated Stars

Those little plastic balls are pickleball’s unsung heroes—and the behind-the-scenes that go into making them is nothing short of fascinating. From the choice of material to the number of holes to the technique used, making pickleballs is an engineering feat that has helped propel the sports to unimaginable heights.